Share

Share

GROWING EXPOSED EPISODE 12:Treedom:

Growing Exposed is a new video series produced by Jeremy Deichen. Coined “the MTV Cribs of the marijuana industry” the show is led by host Amanda Mackay. Growing Exposed has found a unique way to open up the once underground world, revealing the secrets of industry leaders. In addition to garden tours, David Robinson, author of The Grower’s Handbook lends his expertise in a segment entitled Teachings of The Garden Sage. David has dedicated his life to dispelling the myths behind cannabis while educating people on how plants grow.

Season 1 Episode 12

How great would it be to grow the best buds with your best bud? In this episode of Growing Exposed, we take you into a quality growing facility run by childhood friends doing what they love: growing top notch cannabis. You will also learn from the Garden Sage David Robinson why “no small flowers” is key to growing great weed, how to get rebates on your lighting, and how designing the right packaging for your product is one of the most difficult keys to obtain for success–but super rewarding when you get it right.

Right beside a fairly busy crematorium in Bellingham, WA may not seem like the prime location for growing cannabis; the circumstances of its neighbour may even add a veil of eeriness for some visitors. However, this 10,000 square foot facility with a 250 light setup is home to Treedom Productions, ran by Chad and Joe. Growing connoisseur strains such as their Dutch Hawaiian and 9lb Hammer, these friends go into depth over the various time-saving techniques they’ve integrated into their facility.

The dedication to quality is evident. For example, their cannabis never grows something called larf: a fluffy and small material left on the bottom of the plant that is not only time consuming to trim, but there is very little reward trimming it. So, why grow this “larf” at all? Welcome to Treedom Productions, a facility where quality always comes before quantity and the only issue they ever face is “keeping up with demand”ously.

Before entering the veg room, cleanliness is extremely important: you must first spray bleach on the floor–like a doormat–and wipe your shoes. This small but important first step prevents outside pests, diseases, and spores from entering the controlled environment.

Clones are cut off at a 45° angle, dipped in rooting gel, and are rooted in a cloning tray that contains water. Once rooted, these plants are ready to be transplanted into a soil medium in 1 gallon pots and transferred to the veg room. The plants are kept under LED lights, each strain labeled. Once their plants are ready to be transplanted, they are moved into a larger room and put into fabric pots on wheels.

Yes, you read that correctly. Pots on wheels. This “Joe” design makes moving plants easier, especially when they’re moving from veg to flower. Fabric pots, such as brands like Geopot, help aerate the soil and allow the plants to drink faster.

Another great aspect about this facility is their dedication to having their lighting absolutely perfect. Treedom adjusts lights using a parameter from Lightning Electric, who come into the facility and give a full analysis of each individual light. Rob from Lightning Electric uses a meter to record the lighting every week to ensure the plants have the correct distance from the source. This provides the full understanding of what these lights can do and at what height they should be to maximize the plants’ growth. Without the parameter, they could be potentially burning their plants or not giving them enough light. Another great thing about Lightning Electric is they provide a rebate on grow lighting for growers at growrebates.com.

Rolling the plants into the the flower room, they keep it old school with stakes. Every stalk needs to have a stake with ties on it to help support the flowers. Once these plants stop flowering, you can’t control it, it’s already happened in veg. You have to take care of the plant in veg, as the veg stage is more important as it prepares the plants to support huge buds.

The flowering setup at Treedom is extremely labour-intensive, so why not automate it? Well, they don’t, and here’s why: Treedom is all about their high-quality top-shelf nugs, and that is what their consumer base wants time and time again. To maintain that, Treedom has reduced their yield. They could get more weight over the average, but they would rather sacrifice a little yield to keep their product consistent.

Treedom is also not a huge fan of testing THC. Their product is more of a wholesome experience; a connoisseur bud. Treedom models some of their business after the alcohol industry, such as microbreweries. Their product is “more like a wine. You’re not going for what percentage of alcohol is in that bottle, you’re going for the body, legs, what soil it was grown in. The true connoisseur.” Don’t go after the number, just enjoy the product for what it is.

So, what’s all this about big flowers? Why can’t you just grow a bunch more of smaller flowers, isn’t that the same thing? Well, no it isn’t, you want to be able to prune your plants and prune them correctly to get a maximum yield. Here’s why according to the Garden Sage:

“One of my maxims is ‘Don’t grow little flowers’. Why? Because little flowers are terrible to trim, they are usually lower down on the plant, and they are taking away energy from the primary mains that are like our AAA product. Why wouldn’t we want anything other than AAA? Pruning is one of the last things gardeners master, and it takes a lot of confidence to start sculpting our plants to fit into our end picture.

“With many strains, we can start off by doing that at around 6” – 9”. We will not damage the two little growths underneath the terminal node, as each will become a new branch and a new top, and then we can do the same thing again. Really what we are doing is we are directing the plant’s energy to the primary flower sites. If we don’t do that, we are going to end up with a christmas-tree-type structure with A grade, B grade, and C grade plant material because the light is not penetrating down to the bottom and those weaker branches can invite pests and diseases.”

So remember: Don’t grow little flowers and learn the fine art of pruning your cannabis to its maximum level of potential.

Last but not least, it’s time for harvest. After the plants get stripped and cut, they go onto a drying rack that is taken into the drying room. They are dried out over a two week period to cure and allow the terpenes and flavours to really come out. The full size plants remain hanging upside down to allow everything to drain nicely into the buds. Curing the plants must be done in complete darkness, but air circulation must be maintained. Treedom always has consistent airflow of around 2 quarts of air coming through a canned air on a humidity switch. The humidity must remain low so that the buds do not dry out completely, but too high that they end up with bud rot problems. Their humidity is controlled electronically with sensors to maintain a constant humidity level. Curing must take time, and if you don’t take time and flash dry to get product out fast, all the hard work you put into your plants is wasted.

When it’s time to trim, Treedom brings in their sub-contracted trimming team to trim the bud for them and then moves right on to packaging.

For packaging, you have a lot of popular weights that are required: eighths, quarters, halves, ounces, and each store wants different sizes, strains and different amounts. Treedom’s packagers select the best nugs for the size, package them up and the products are sent out to stores.

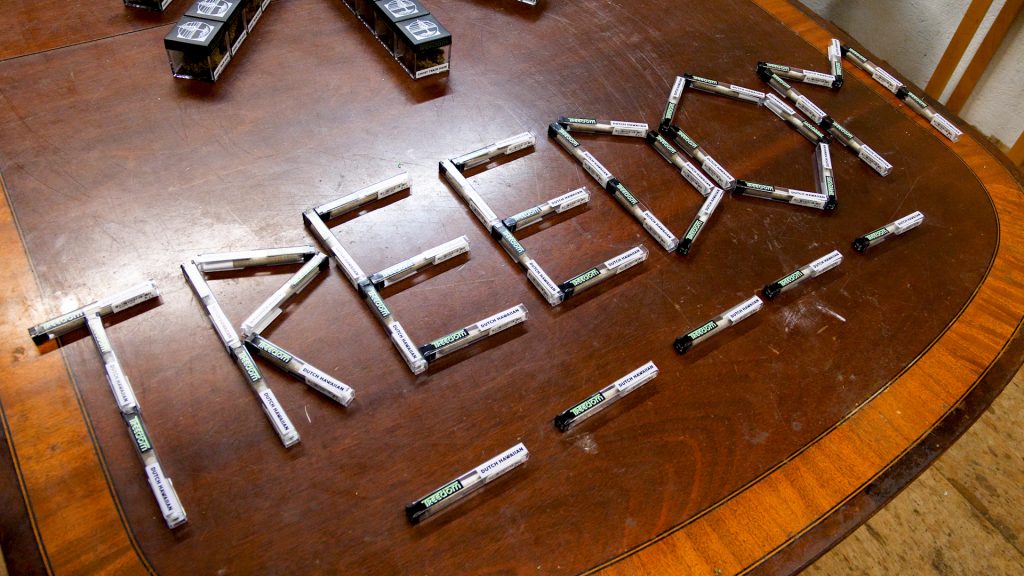

Treedom decided on a slick premium-looking container for packaging their product after a lot of research and found a company to manufacture acrylic cubes for them. This extra effort in packaging really sets Treedom apart from competitors as their product remains fresher longer,has more shelf-appeal, easily stackable, fits together nicely, and most importantly and is eye-catching to customers. For specific stores, Treedom also leaves buds on the cola. They weigh it out extra to compensate for the stem and sell as-is as one beautiful nug.

“We are so happy with the name, the logo, the brand, the product… over all the way this all turned out… this is amazing. More than we could hope for. “

In this episode of Growing Exposed, we looked at a facility that put quality first over quantity and even THC numbers, why pruning your plants is crucial to growing consistent AAA cannabis, the importance of lighting parameters, and why sometimes, you just have to take your time and make sacrifices for the better good of your product. Treedom is a great example of this ideology from clone all the way to the shelf appeal of their final product. For more Growing Exposed, and for behind-the-scenes, tune in at GrowingExposed.com and make sure to follow Growing Exposed on Facebook and Instagram.