Share

Share

Growing To New Heights

Season 1 Episode 2

Amanda Mackay hosts the premiere episode of Growing Exposed, the show that takes you inside the world of marijuana growing and introduces you to some of the characters behind these gardens. Created by film producer Jeremy Deichen, this series takes a look into the once underground world of marijuana production; documenting garden tours, revealing product tips, and reviewing products and practices.

What happens, as a grower, when you have a football-field-sized warehouse at your disposal? The answer is pretty obvious: you fill it with green.

This episode of Growing Exposed features a grow unlike anything you’ve ever seen: cannabis plants as tall as trees, buds as big as two-litre bottles, and terminal buds the size of a man’s head; this particular grow is anything but traditional.

Although the garden is a licensed facility, no one wished to be on camera. So, we got veteran grower, YouTube educator, and activist Jason Wilcox, founder-director of the Cannabis in Canada society, to be our guest garden-tour-guide.

Jason first takes us to the roof, where he reveals the high-tech equipment this grow uses to control their growing facility, from lighting, climate control, water filtration and more. The roof itself features a vast number of ballasts and each room is cooled by three 5-tonne Air Conditioning Units. The grow-op also features an activated charcoal filter to clean the air going out of the facility (known as a scrubber), a dehumidifier which recycles the water the plants transpire back into the system, a high-end water filtration system that removes both chlorine and chloramine (which is damaging to crucial inoculants), a water chiller to keep water at a steady 70°F, and to top it off, each room is certified fire-safe. Every single component is wired for precision and efficiency.

As this grow uses a recirculating hydroponics system, they steer far away from traditional growing methods and hone the advantages of high-tech growing technology. The reservoir is where nutrients, and in this particular growers case, dissolved oxygen which supports root aeration, are injected directly into the water. This grower uses GP3, a 3-part nutrient system by Green Planet Nutrients, as their choice base nutrient system. The system was created through years of scientific research looking for better and more efficient ways to grow in hydroponics systems, soilless growing mediums, and in soil.

“It’s an amazing product. This particular grower is running a hydroponics system and the results are phenomenal. You’ve got your bloom, your veg, your micro,” explains Wilcox. “It is referred to as a 3 part nutrient because all are used simultaneously depending on the life stage of the plant.”

Moving to the propagation room, where the facility keeps a room packed full of mother of optimal phenotypes and hybrid strains, it is a forest of ganja. However, how do you select a mother plant? The keen knowledge of David Robinson, the Garden Sage, tells us how this is achieved.

Robinson explains that it takes roughly 6-9 months to identify the best phenotype out of a batch of seeds, which becomes your mother plant. The mother plant is sustained in vegetative growth, so it is kept under a constant 18 hours of light a day. This plant will never flower, but the clippings taken from the plant, which have a rooting hormone applied to the stem to encourage roots to form and thus create a “clone”, are grown to bloom.

By controlling your own genetics and growing clones of your most favourable phenotype, you eliminate problems associated with outsourcing and can achieve a predictable growth pattern, maintain good genetics, and consistently pump out high quality product. Flowering rooms are kept under 12 hours of light a day to induce flower, typically under a red-spectrum light such as high pressure sodium bulbs. Vegetative rooms are always kept under 18 hours of light a day and normally use blue-spectrum light, typically a metal halide light. Blue light boosts a plant’s immune system, keeps nodes short and compact, keeps inter-nodal spacing tight, and gives the ideal veg growth pattern for big and multiple flowers. When you can consistently on a schedule move plants in and out of growth, veg, and harvest, all these elements form the most important aspect of a business operation: efficiency.

With optimal air flow, a tightly controlled climate and constantly monitored PH, PPM and temperature levels, the plants in this football-field-sized facility are allowed to grow to incredible heights. In the flower chamber, huge, luscious buds the size of Jason’s head are frosted in trichomes, but when it comes time to harvest, a grow this size can become tedious and highly labour intensive.

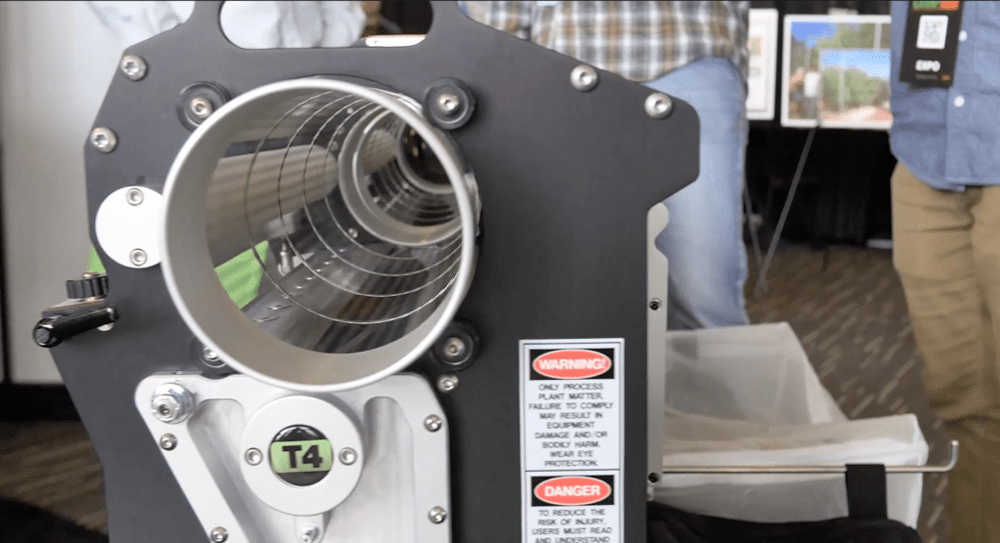

Keirton, a company that manufactures the Twister, a wet and dry trimmer for the cannabis industry, saves the day. With conveyor belts and all sorts of high-tech machinery, this trimmer can wet-trim an incredible 9lbs of cannabis in an hour, which is a necessity for a grow this scale.

So, you’ve seen big buds, massive marijuana plants, cool grow-tech, and a high-tech recirculating hydroponic growing facility the size of a football field. Is this the cannabis grower’s Garden of Eden, or is this just the start of something bigger? Make sure to tune into Growing Exposed to learn more about the behind-the-scenes of growing cannabis.