Share

Share

Double Decked Growing

Season 1 Episode 3

Amanda Mackay hosts the premiere episode of Growing Exposed, the show that takes you inside the world of marijuana growing and introduces you to some of the characters behind these gardens. Created by film producer Jeremy Deichen, this series takes a look into the once underground world of marijuana production; documenting garden tours, revealing product tips, and reviewing products and practices.

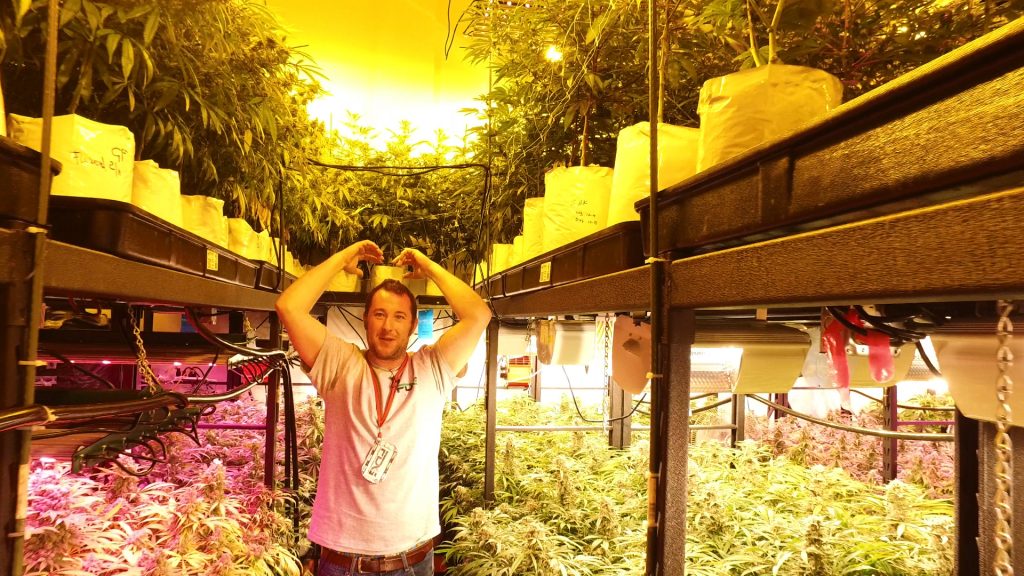

What do a double-decker bus and a cannabis garden have in common? In this unique situation, the use of vertical space to fit as much as possible into a small area.

When you’re the first legal facility in your location, finding a location can prove difficult as many businesses are apprehensive about having a marijuana grow in their area. For this reason, the selection of potential facilities is limited, so a small unit in an industrial park seems like a fair compromise.

According to the expert knowledge of David Robinson, it’s important to note that environment isn’t everything. You can have strong genetics with a mediocre environment and still get a good yield. However, mediocre genetics in an ideal environment will still only give you an average yield. Having strains with strong genetics allows Fine Detail Greenway to pump out good yields consistently.

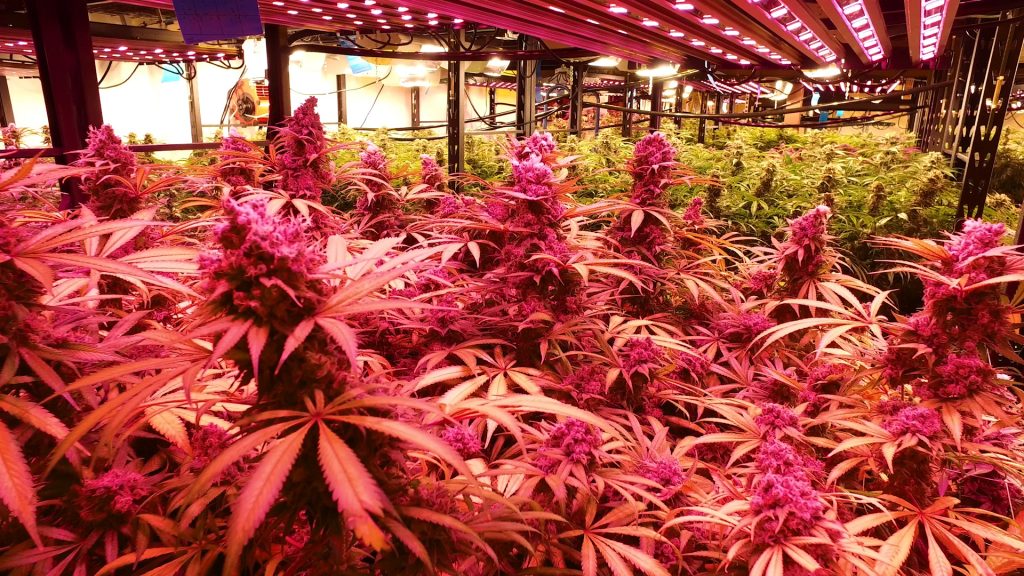

In the flowering room, there are always new plants coming in and ready plants coming out for harvest. They have six feet of growing room per deck, and although it seems like a small amount of space, keeping the plants short is beneficial as there is not enough room to raise the lights and reduce heat if the plants grow tall, which can damage them and thus minimize yield.

Even though every indoor garden situation is different, the basic fundamentals remain the same. Plants grown indoors require light, nutrients, and climate control, to name a few.

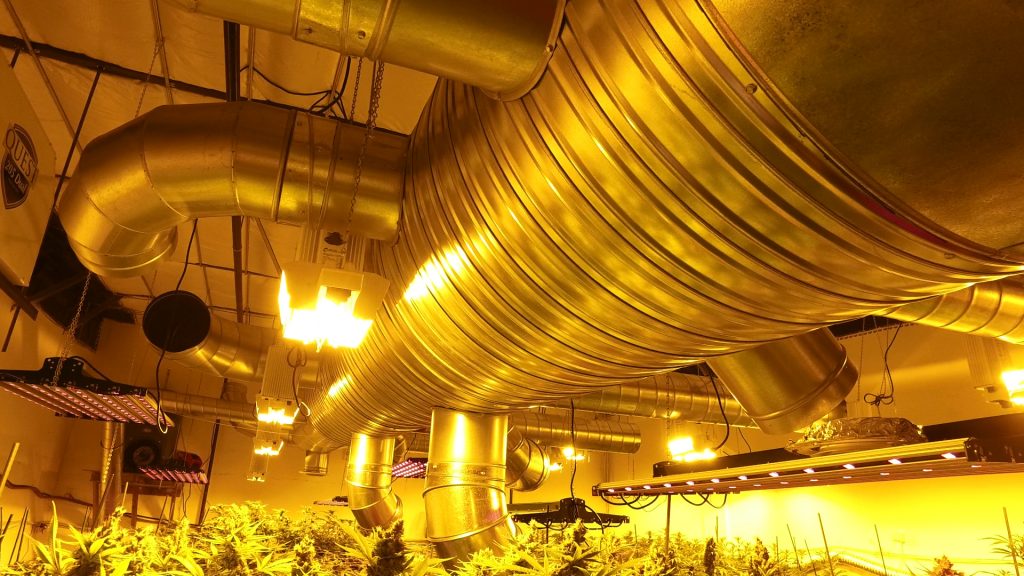

As this garden is stacked, air movement is a little difficult. Fine Detail Greenway combats this by having air-circulating fans in every area possible, combined with a double-insulated roof to minimize damage to the facility from transpired water and a vapor barrier to keep outside air from coming in.

In order to combat heat issues from their many LED lights, they have a 25 tonne train air conditioning unit that goes throughout the facility. The ACU was structurally engineered to be put on the roof with solid steel beams set 6 feet into the ground to support it, each of the four steel beams reinforced with a full cement-truck-worth of cement. Smell is taken care of by a large carbon filter that scrubs the air leaving the facility to eliminate odour.

With high-tech gear, keeping logs of the nutrients, ppm, pH levels, and temperature of their environment and reservoirs, Fine Detail Greenway is able to maintain an ideal growing situation. However, pests can still be a problem. As cannabis is a crop that people consume, pesticides are completely out of the question, not to mention terrible for the environment. Fortunately, there are ways to combat pests without the need for pesticides.

Fine Detail Greenway uses predatory insects to combat pests. Two of the predatory insects they use are Stratios-S, aka “strats”, which are soil mites who prey on the larvae of fungus gnats, and Phytoline P, a predatory mite that preys on spider mites. As they are bigger and faster than spider mites, a small teaspoon of Phytoline P will travel throughout the crop and devour the spider mites. Using predatory bugs is a natural and efficient way to combat pests, and an order can be received in a couple of days. Minimal effort for the grower and entirely beneficial for the plants.

Keeping their harvest small and harvesting often allows for a consistent export of cannabis. Not being overwhelmed by a massive yield harvested at once, they can trim every day and can ship out product every week. A group of three trimmers is then able to manage a harvest that would take twenty trimmers to do, which is far more cost-efficient. The product is then packaged and shipped off to retail stores for people to enjoy.

Now, you’ve seen a peek into an industry that is in its fruition, with tech, gear, and more dedicated to the cultivation of legal marijuana. A vertical-stacked system allows the grower to produce a similar yield as a facility with twice the floorspace, which showcases the awesome variety and engineering of indoor growing. Make sure to tune into Growing Exposed to learn more about the behind-the-scenes of growing cannabis.